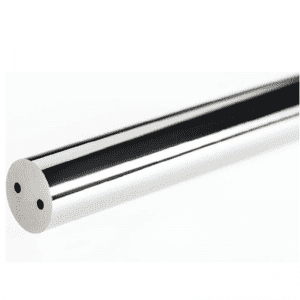

안정적인 고품질의 엔드밀 및 드릴용 텅스텐 솔리드 카바이드 로드

1. 텅스텐 솔리드 카바이드 봉은 성형 또는 압출에 의해 프레스 성형됩니다.

2. 텅스텐 솔리드 카바이드 봉은 저압 소결 통합로에 의해 소결되므로 전반적인 성능이 높습니다.

3. 거친 텅스텐 - 코발트 카바이드 원형 막대 또는 원형 막대의 외경은 공차에 따라 세련되고 연마 될 수 있습니다. 일반적인 공차는 h5,h6, -0.005 등이며 카바이드로드 끝 모따기도 처리 할 수 있습니다.

4. 카바이드 봉은 일반 강, 주철, 스테인리스 강, 내열 강, 니켈 계 및 티타늄 합금의 가공에 적합합니다. 트위스트 드릴, 엔드밀, 탭 및 건 드릴과 같은 범용 초경 공구 재료에 권장됩니다.

탄화물 막대의 우리의 유형

1. Unground 긴 막대

| TOL. Unground 긴 막대의 | ||

| 크기(DxL,mm) | 용인 | |

| D(mm) | L(mm) | |

| D[1-3)x310/330 | 0.30~0.55 | 0.00~+4.00 |

| D[3-12)x310/330 | 0.30~0.60 | 0.00~+4.00 |

| D[12-20)x310/330 | 0.30~0.65 | 0.00~+4.00 |

| D[20-40]x310/330 | 0.30~0.70 | 0.00~+4.00 |

2. 길이에 따라 절단되지 않은 막대

| TOL. 절단되지 않은 길이의 막대 | ||

| D/L(mm) | TOL.of D&L(mm) | |

| L<=70 | 70<L<=150 | |

| D<5 | D(0.20~0.30), L(0.20~1.5) | D(0.25~0.35), L(0.20~1.5) |

| 5<=D<40 | D(0.25~0.35), L(0.20~1.5) | D(0.30~0.40), L(0.20~1.5) |

3.Ground long rods

The tolerance of the long rods is h5/h6 or at customer’s requirement in Dia. ,and 0.00~+5.00mm in Length as normal.

4.Ground cut-to-length rods

The tolerance of the ground cut-to-length rods is h5/h6 or at customer’s requirement in Dia. ,and 0.00~+2.00mm in Length as normal.

5.PCB Rods

more than 50 years production and management experience,Advanced production technology, High-precision machines, Strict QC management system, Special-designed packing boxes and tubes, Various shipping methods

1.Tungsten carbide blanks production

Good quality carbide products rely on 100% virgin raw materials and advanced wet-milling,pressing machines and sintering furnaces. We put emphasize on every production process of our carbide blanks. To keep good quality of carbide blanks is the base of furtherly machined high precision finished carbide parts.

2.Inspection and testing process

In order to ensure the quality of all our tungsten carbide finished products, a very strict QC management system we called “Quality Control Center” has been introduced. With our advanced inspection equipment and our professional inspectors, we are able to do raw materials inspection, on-site inspection and after finishing inspection to ensure 100% good quality of your carbide products.

3.Advanced CNC Equipment

NCC owns a series of high-precision grind machines, including flat grinding machines, OD and ID machines, Centerless grinding machines and customized grinders. Also we have CNC machines, EDM, Wire-cutting machines and drilling machines etc. With our skilled workers, we can control very high precision of each carbide part.

4.Packaging and Shipping

Special-designed packing boxes and tubes will be used properly for the standard and customized carbide products to ensure the safety of the goods during the transportation process.A wide range of shipping ways can be available for your shipments, for example we can ship goods by Sea, by air and by Express companies like DHL/FedEx/UPS/TNT etc.